Table of Contents

- Introduction to TMT and HYSD Bars

- What Are TMT Bars?

- Key Features of TMT Bars

- Benefits of Using TMT Bars

- What Are HYSD Bars?

- Key Features of HYSD Bars

- Benefits of Using HYSD Bars

- TMT vs. HYSD: Key Differences

- Manufacturing Process

- Strength and Flexibility

- Corrosion Resistance

- Which Is Better for Your Project?

- How Goel World Supplies Top-Quality TMT and HYSD Bars

- Conclusion

- FAQs about TMT and HYSD Bars

1. Introduction to TMT and HYSD Bars

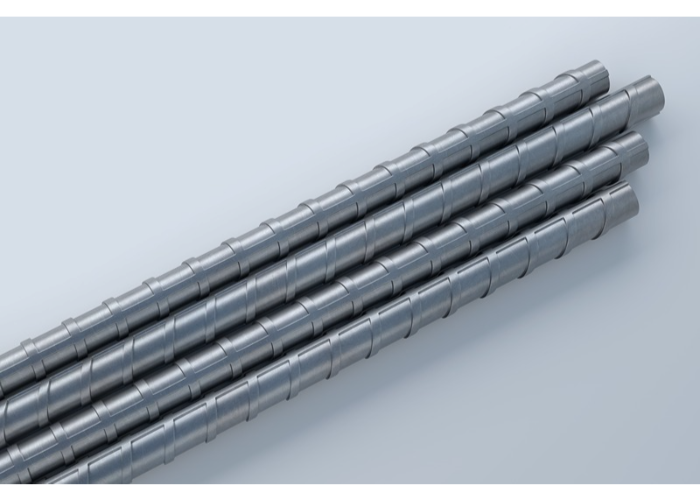

When it comes to reinforcing concrete in construction, TMT (Thermo-Mechanically Treated) and HYSD (High Yield Strength Deformed) bars are two popular choices. Both types of steel bars offer great strength and are widely used in building foundations, columns, and beams. However, there are key differences between the two that can influence which is better suited for your construction project. This article explores the features, benefits, and differences between TMT and HYSD bars, helping you make an informed decision. Goel World, a leading supplier in Lucknow, provides both TMT and HYSD bars to ensure you get the best materials for your needs.

2. What Are TMT Bars?

Key Features of TMT Bars

TMT bars are steel bars that undergo a specialized thermo-mechanical treatment process. This process involves passing the steel through a high-temperature rolling mill and then rapidly cooling the outer surface while the core remains hot. This creates a strong outer layer with a softer, ductile core, making TMT bars both strong and flexible.

Benefits of Using TMT Bars

- High Strength and Ductility: TMT bars are known for their high tensile strength and flexibility, allowing them to withstand significant stress without breaking.

- Corrosion Resistance: The thermo-mechanical treatment process ensures that TMT bars have superior resistance to rust and corrosion, making them ideal for projects exposed to moisture or humid conditions.

- Earthquake Resistance: Thanks to their flexibility, TMT bars can absorb and dissipate seismic energy, making them perfect for construction in earthquake-prone areas.

- Fire Resistance: TMT bars can endure high temperatures without losing strength, ensuring the stability of structures in case of a fire.

3. What Are HYSD Bars?

Key Features of HYSD Bars

HYSD bars are high yield strength deformed steel bars. These bars are produced through a cold twisting process where the steel rods are twisted to create deformation patterns along their surface. These deformations provide a better grip between the steel bar and concrete, increasing the bond strength.

Benefits of Using HYSD Bars

- Enhanced Grip: The deformations on the surface of HYSD bars improve bonding with concrete, making them suitable for structural applications where firm attachment is needed.

- Higher Yield Strength: HYSD bars offer higher yield strength compared to regular steel bars, making them an economical choice for large-scale construction projects.

- Cost-Effective: HYSD bars are generally more affordable than TMT bars, making them a popular option for budget-conscious projects without compromising on strength.

4. TMT vs. HYSD: Key Differences

Manufacturing Process

- TMT Bars: Manufactured using a thermo-mechanical treatment process that combines heat and water quenching, giving TMT bars a unique microstructure with a tough outer layer and ductile core.

- HYSD Bars: Produced through a cold twisting process that involves physically twisting the steel to create surface deformations, leading to higher yield strength but less flexibility compared to TMT bars.

Strength and Flexibility

- TMT Bars: Known for their combination of high strength and flexibility, making them ideal for structures requiring resilience against dynamic loads, such as earthquakes.

- HYSD Bars: While they offer high yield strength, HYSD bars are less flexible and may be more prone to brittleness under certain conditions.

Corrosion Resistance

- TMT Bars: Have superior resistance to rust and corrosion due to the thermo-mechanical treatment process, making them suitable for projects in coastal or humid areas.

- HYSD Bars: Offer less resistance to corrosion compared to TMT bars and may require additional protective measures when used in moisture-heavy environments.

5. Which Is Better for Your Project?

The choice between TMT and HYSD bars largely depends on the specific requirements of your construction project. For projects in earthquake-prone areas, TMT bars are the better choice due to their flexibility and earthquake resistance. If your project is located in a coastal or humid region, TMT bars’ superior corrosion resistance makes them the optimal choice. However, for large-scale projects that prioritize yield strength and cost-effectiveness, HYSD bars may be more suitable.

Goel World offers expert advice to help you decide which type of bar is best for your project, ensuring that you have the right materials for a durable and resilient structure.

6. How Goel World Supplies Top-Quality TMT and HYSD Bars

Goel World, a leading supplier of construction materials in Lucknow, provides both TMT and HYSD bars of the highest quality. We source our products from trusted manufacturers to ensure that they meet industry standards for strength, durability, and performance. Whether you need TMT bars for earthquake resistance or HYSD bars for cost-effective reinforcement, our knowledgeable team is here to guide you through the selection process. With over 25 years of experience in the industry, Goel World is your reliable partner for all your reinforcement needs.

7. Conclusion

Both TMT and HYSD bars have their own strengths and applications, making them suitable for different types of construction projects. TMT bars offer superior flexibility, corrosion resistance, and earthquake protection, making them ideal for projects in challenging environments. HYSD bars, on the other hand, are a cost-effective solution for projects requiring high yield strength. By understanding the differences between these two types of reinforcement bars, you can make an informed decision that best meets your construction requirements. For high-quality TMT and HYSD bars, Goel World is the go-to supplier in Lucknow, ensuring you get the best materials for your project.

8. FAQs about TMT and HYSD Bars

Q1: Which is stronger, TMT or HYSD bars?

TMT bars are generally considered stronger due to their combination of tensile strength and flexibility, while HYSD bars offer high yield strength but less flexibility.

Q2: Are TMT bars better for earthquake-prone areas?

Yes, TMT bars are highly recommended for earthquake-prone areas due to their superior flexibility and ability to absorb seismic forces.

Q3: Can HYSD bars be used in coastal regions?

HYSD bars can be used in coastal areas, but additional protective measures like anti-corrosion coatings may be required due to their lower corrosion resistance compared to TMT bars.

Q4: What are the cost differences between TMT and HYSD bars?

HYSD bars are generally more affordable than TMT bars, making them a budget-friendly option for projects with lower corrosion or flexibility requirements.

Q5: Where can I find high-quality TMT and HYSD bars in Lucknow?

Goel World offers top-quality TMT and HYSD bars, ensuring that your project benefits from the best reinforcement materials available.